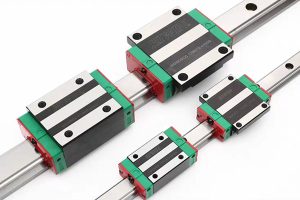

Linear guides are critical components in various industrial applications, ensuring precise linear motion in machinery such as CNC machines, robotics, and automated systems. Proper maintenance is essential to extend their lifespan, maintain accuracy, and prevent costly downtime. Here are key practices for effective linear guide maintenance.

1. Regular Cleaning

Dust, debris, and contaminants are primary enemies of linear guides. Accumulated particles can cause abrasive wear, increasing friction and reducing precision. Clean the guides regularly using a soft brush or lint-free cloth. For stubborn dirt, use a mild solvent like isopropyl alcohol, avoiding harsh chemicals that may damage seals or surfaces. Ensure the environment is kept clean to minimize contamination.

2. Lubrication

Adequate lubrication reduces friction, prevents wear, and dissipates heat. Use the manufacturer-recommended lubricant (grease or oil) suitable for the application’s speed, load, and temperature. Apply lubricant evenly along the rail and ball screws, following a scheduled routine—typically every 500 to 1,000 operating hours. Avoid over-lubrication, as excess lubricant can attract dust. For demanding environments, consider automatic lubrication systems.

3. Inspection

Conduct routine visual and operational inspections. Check for signs of wear, such as scratches, corrosion, or discoloration on the rails and blocks. Listen for unusual noises like grinding or squeaking, which may indicate inadequate lubrication or damage. Measure the motion for smoothness and accuracy; any deviation could signal misalignment or wear. Replace worn components promptly to avoid further damage.

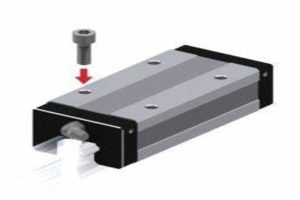

4. Alignment and Installation

Misalignment accelerates wear and reduces performance. Ensure proper installation and alignment during initial setup and after maintenance. Use precision tools to verify that rails are parallel and level. Tighten bolts evenly to the specified torque to avoid distortion. If machinery is relocated or subjected to vibration, recheck alignment periodically.

5. Environmental Protection

Protect linear guides from harsh conditions. In humid or corrosive environments, use stainless steel guides or apply protective coatings. Install seals or bellows to shield against dust, chips, and liquids. Control temperature fluctuations, as extreme heat or cold can affect lubrication and material dimensions.

6. Training and Documentation

Train personnel on proper maintenance procedures and safety protocols. Keep detailed records of lubrication schedules, inspections, and replacements. This helps track component history and plan preventive maintenance.

Areswin Precison Machinery can aupply all kinds of lienar gudie. such as: THK, HIWN,CPC,NSK,TBI,PMI,Rexroth,ABBA, If you need please contact us, we will give you a good feedback. Plesae contact us here:www.areswin.net

In summary, consistent cleaning, lubrication, inspection, and environmental control are vital for linear guide upkeep. By adhering to these practices, you can ensure reliable performance, enhance machine longevity, and optimize productivity in industrial operations.