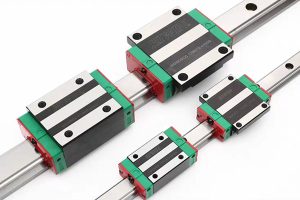

PMI (Precision Motion Industries) linear guides are widely recognized in the automation and machinery industries for their high precision, durability, and reliability. These linear motion systems are essential in applications requiring smooth and accurate movement, such as CNC machines, robotics, medical equipment, and semiconductor manufacturing. Below are the key advantages of PMI linear guides.

1. High Precision and Accuracy

PMI linear guides are designed to provide exceptional precision, ensuring minimal deviation during linear motion. The high-quality manufacturing process and strict tolerances reduce backlash and vibration, making them ideal for applications where accuracy is critical. This precision enhances the performance of automated systems, leading to better product quality and consistency.

2. Smooth and Low-Friction Movement

The rolling elements (such as balls or rollers) in PMI linear guides ensure smooth motion with very low friction. This reduces energy consumption and wear, prolonging the lifespan of both the guide and the machinery. The low friction also allows for high-speed operation without compromising stability, making PMI guides suitable for dynamic applications.

3. High Load Capacity

PMI linear guides are engineered to handle heavy loads, including radial, axial, and moment loads. Their robust construction distributes weight evenly across the rail and carriage, preventing premature wear. This high load capacity makes them suitable for industrial machinery, heavy-duty automation, and large-scale manufacturing equipment.

4. Durability and Long Service Life

Made from high-quality materials such as hardened steel or stainless steel, PMI linear guides are resistant to wear and corrosion. The precision-ground rails and carriages ensure consistent performance even under demanding conditions. Additionally, many PMI guides come with protective seals or coatings to prevent contamination from dust, chips, and moisture, further extending their lifespan.

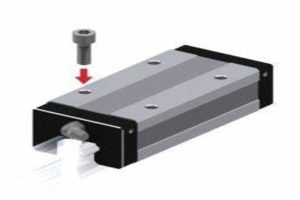

5. Easy Installation and Maintenance

PMI linear guides are designed for straightforward installation, often featuring pre-drilled holes and standardized dimensions for compatibility with various machinery. Maintenance is minimal due to their self-lubricating design or the availability of lubrication options that reduce the need for frequent servicing. This ease of use helps minimize downtime and operational costs.

6. Versatility in Applications

PMI offers a wide range of linear guide models, including miniature guides for compact applications and heavy-duty versions for industrial use. Their versatility allows them to be used in diverse industries such as aerospace, automotive, medical devices, and 3D printing. Customizable options, such as different rail lengths and carriage types, ensure compatibility with specific application requirements.

7. Cost-Effectiveness

Despite their high performance, PMI linear guides are competitively priced compared to other premium brands. Their durability and low maintenance requirements contribute to long-term cost savings by reducing replacement and repair expenses. This makes them an economical choice for businesses seeking reliable motion control solutions.

8. Quiet Operation

The precision engineering of PMI linear guides minimizes vibration and noise, making them suitable for environments where quiet operation is essential, such as medical and laboratory equipment.

Areswin Precision Machinery Company can supply PMI original Linear Guide. Please click here for more information: PMI – ARESWIN

Conclusion

PMI linear guides offer a combination of precision, durability, load capacity, and cost-effectiveness, making them a preferred choice for various industrial and automation applications. Their ability to enhance machine performance while reducing maintenance needs ensures long-term reliability, making them a valuable investment for manufacturers and engineers worldwide. Whether for high-speed automation or heavy-load machinery, PMI linear guides provide the accuracy and efficiency needed for optimal performance.