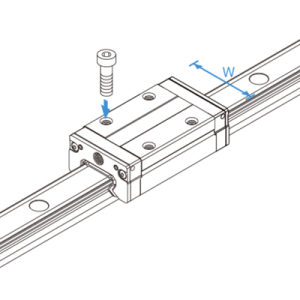

A structure with a wide rail width and low center of gravity. SHW It is advantageous when there are Mc moment requirements and is thin compared with.

THK SHW guides are engineered for applications demanding exceptional rigidity, load capacity, and accuracy under heavy loads. They are a premium choice in industries where machine performance and longevity are critical.

Key Characteristics:

-

High Rigidity & Load Capacity: Designed with large ball circuits and robust carriage/saddle constructions to handle very high loads (both dynamic and static) without deformation.

-

Pre-Grinding Technology: The raceways and rails are often pre-ground to extremely tight tolerances, ensuring high running accuracy and smooth motion.

-

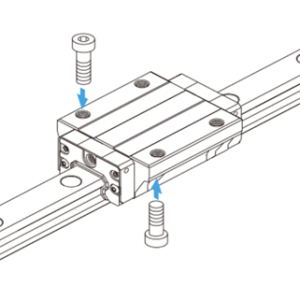

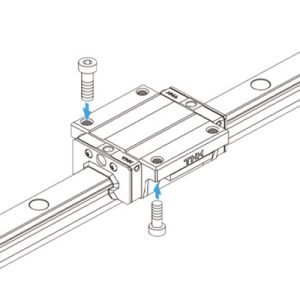

Sealing & Lubrication: Excellent sealing systems to protect against contaminants (chips, dust, coolants) in harsh machine tool environments. Often feature efficient re-lubrication systems.

-

Wide Product Range: Available in a vast range of sizes, from compact guides to very large models with rail widths exceeding 200mm.

-

Integrated Designs (Saddle-Type): A hallmark of THK SHW is the “SVS” series – where the guide carriage is integrated into a massive, machinable saddle plate. This simplifies machine design, increases rigidity, and allows for direct mounting of other components.

Typical Applications:

THK SHW guides are found in high-end capital equipment:

-

Machine Tools: Machining centers, grinding machines, milling machines, boring mills.

-

Precision Assembly & Inspection Machines

-

Semiconductor Manufacturing Equipment

-

Large-Scale Industrial Automation & Gantry Systems

Model: SHW12CAM,SHW14CAM,SHW17CAM,SHW21CAM,SHW27CAM,SHW35CAM,SHW502CAM